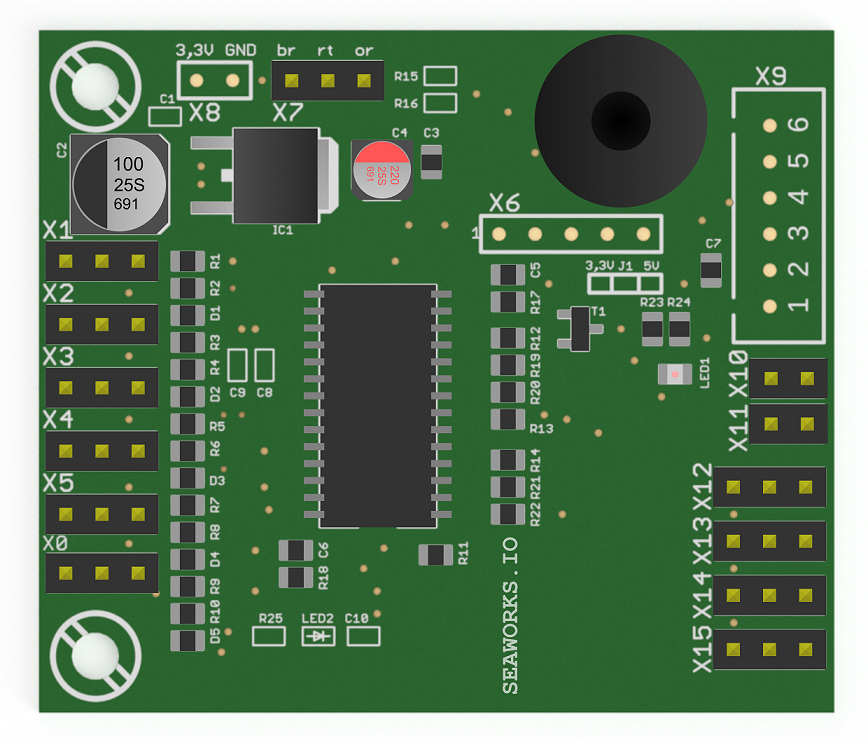

A new General-Purpose module

In late 2022 we choose to sell public one of our niche products. This board was born a few years ago as a simple interface to reliable control servos of robots and aid during the prototyping phase.

Its main purpose is to get rid off typical protoype configurations (Arduino, breadboard, some resistors plugged in, crappy power delivery) and offer a reliable production like environment for servos/actuators with solid power management.

Initially designed like a soldered mini-board, we later designed our CLIM module to be able to fulfill this function too, with just some little adjustments during the manufacturing process. In this way we can guarantee a Industry-grade design, which the CLIM is, for this project.

Aside the control servos, you'd be also able to control ESCs and read values from up to five (5) PWM sources. The other main advantage is the electrical isolation from the processor (Arduino, Raspberry Pi, Whatever else) from the power electronics and leave this concerns entirely to this module.

The module communicates with other devices through UART, one of the simplest but still reliable serial implementations, with a series of easy and short commands. Our simple protocol uses a software flow control, more about it here.

We tried to keep the UART read latency inside the module controller close to zero, the response of the overall system mostly depends from the control part (Arduino code, Python program on Raspberry Pi) and how those interfaces are addressed. In most cases the servo response is fast enough for any sensor controlled system (20-30 ticks per second).

When performing a complete Read-Compute-Write cycle (Read PWM, send through UART, compute, resend through UART, Write PWM) the latency can increase a bit more. In our lab test those values are still more than acceptable for automated systems. Truly real-time critical system like control surfaces on a Rocket may not work well tho, we don't reccomend the module for these use cases.

A summary of the features:

- 5 inputs @ PWM (700 - 2300 us)

- 4 outputs @ PWM (700 - 2300 us)

- 3.3V / 5V UART interface

- 5V distribution rail with BEC connector

- Dimensions: 56 x 48 x 13 mm

We ship the Serial-Servo-Hub with a little test program (link on the project page) and some example scripts in Python.

This spring we also plan to roll-out our more advanced CLIM Pro kit with the VSP PODControl module, which will fit the requirements for complex vessel control. The development of the VECTOR platform based on STM32 is also ongoing and we aim for a presentation later this year.

That's all for now, more updates about the VSP PODControl will follow in the next weeks.